Kaliningrad Package Factory (KTK) is the number one Russian producer of metal containers and packaging. KTK supplies more than 20% of Russia’s can market.

The factory has maintained its dominant position for the past five years. It is also the country’s largest exporter of cans, with a share of over 60% of Russia’s total can exports.

Traditionally, metal cans account for the highest proportion of our production volume. We sell to the leading fish and meat processing companies in Kaliningrad Region and other parts of Russia, and we have formed stable, long-term business relationships with many of them.

In addition, our firm produces canned meat and fish under our own brand, Sokhranim traditsii (Preserving Traditions). The plant has a production capacity of 10 million cans of food per month. Our specialists place great importance on adhering to traditional methods and recipes. The calibre of our raw materials, the very latest imported equipment, progressive technologies, a modern laboratory, and strict quality control of the end product mean that we can produce competitive and high-quality goods. Our merchandise has long been in high demand in many parts of Russia.

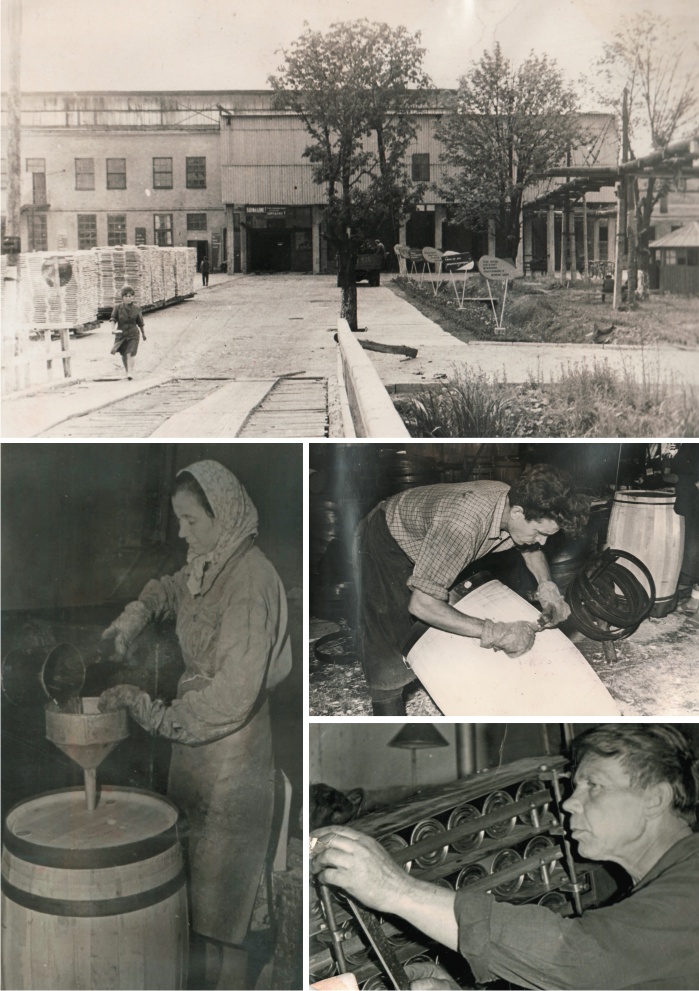

We like to preserve the best of our heritage. While adopting modern technologies and the latest equipment, we remain true to the traditions of quality and the work ethic established more than half a century ago.

Investments in the Future

The history of metal can production goes back more than 100 years. However, we use only the latest technology and materials in our production process.

We use tin plate made by European manufacturers in accordance with the EN 10202 standard and tin produced by Russia’s leading factories in accordance with GOST 13345-85. For tin plate varnishing and lithography, we use only European materials, which can be used for canning a full range of meat, fish, fruit, and vegetables. All our metal containers are made of raw and finished materials authorized for contact with food products by Russia’s healthcare agencies and the Federal Service on Customers’ Rights Protection and Human Well-Being Surveillance.

Kaliningrad Package Factory’s production facilities are fitted with modern, reliable, high-productivity equipment made by leading European companies.

To produce welded composite cans, we use Soudronic (Switzerland) lines; to produce lids and bases we use Karges Hammer (Germany), Cevolani (Italy), and Cantec (Germany) high-speed presses; for production of seamless metal cans and their ends, and for EOE83 and EOE99 easy-open lids, we use Alfons Haar (Germany) presses; for coating tin plate using a system for drying coated materials with gas, we use modern KBA MetalPrint (Germany) lines, and for packing metal containers onto pallets of different formats, we use Clevertech (Italy) automated palletizers. KBA MetalPrint's four-colour printing machine, MetalStar-2 (Germany), ensures high-quality lithographic production on can lids and cases. Modern pre-print preparation technology from AGFA Graphics (Belgium) allows us to significantly reduce printing time.

COMPANY'S MISSION

Our combine - a well-deserved enterprise with vast experience and a long history - not only produces high-quality metal packaging and produces canned products according to traditional recipes. Every year the consumer value of our products grows and contributes to the development and prosperity of the enterprise in the interests of shareholders, employees, partners and customers.

TARGET

Take the leading positions in branch, to be ahead of competitors on quality, equipment, innovations to keep authority and recognition of consumers.

POLICY OF THE FACTORY

Quality. The factorye's activities are inextricably linked with the concept of quality, meet the requirements of the international standard. The products of the enterprise should not only comply with officially established norms, but also exceed consumer expectations, both in Russia and abroad.

Innovation. The main condition for the continuous development of the enterprise is the introduction of the latest equipment, the use of the latest technologies, the optimization of production and logistics.

Efficiency. The factory has a powerful production and technical base, a considerable intellectual property and a commercially profitable enterprise, which ensures positive dynamics of economic indicators and financial stability.

Legality. The enterprise carries out commercial activities in full compliance with the laws of the Russian Federation, it is absolutely legal and transparent for both the founders and any inspection bodies.

Professionalism. The personnel of the factory is a source of strength, intellectual potential and corporate culture. The concern of the enterprise about specialists is expressed in providing optimal working conditions, opportunities for training, improving skills, personal and career growth, implementing an effective system of motivation for each employee, creating an atmosphere of trust, respect and mutual assistance in the team.

A responsibility. A good name enterprise is a resource that every employee of an enterprise should value, not only at work, but also outside the workplace. It consists of punctual fulfillment of obligations to suppliers and consumers, each of which, in fact, is a partner of the plant.

The management of OJSC "Kaliningrad Package Factory" undertakes obligations to ensure the implementation of this Policy and calls on the whole team of the enterprise.

On 5 October 1950. the Council of Ministers of the USSR approved a resolution to build a barrel factory in Kaliningrad.

1952 On 12 March. the Kaliningrad Barrel and Box Factory produced its first goods, marking the beginning of the company’s illustrious history.

1957. In accordance with the decision of the Presidium of the Supreme Soviet and the Council of Ministers of the RSFSR, the Barrel and Box factory was merged with a wooden packaging plant.

1968. The factory’s cardboard shop began to manufacture cardboard packing boxes.

1973. Following the merger of the Barrel and Box Factory with the Metal Can Factory, a varnish printing shop and a metal can shop were added to the main barrel, wood processing, container repair, and cardboard shops. Since then, the company has borne the name of Kaliningrad Package Factory.

1975. An automated ETTENAUER varnishing line from Austria was installed and put into operation; Karges Hammer automatic presses for the manufacture of seamless cans were introduced. A production line made by West Germany’s Krupp was commissioned for the manufacture of can No. 27, made from tin and aluminium. A new film-processing division was opened to make templates for the varnish printing and cardboard shops.

1977. A complex quality control system was developed at the plant based on the regulation system at Yaroslavl Engine Plant. A standard entitled ‘Intra-Factory Product Quality Certification’ was introduced to the list of standards.

1978. A new shop for the production of a modern type of packaging – polyethylene containers – was commissioned.

1995. The barrel and wood processing shops were closed.

2000. An automatic metal can production line was launched.

2001. Soudronic production lines were acquired and commissioned for the production of three-component composite metal cans using a seam welding process, a fundamentally new product to Russia. By the end of the year, productivity had risen to 30,684,000 metal containers per month.

2002. Having set its sights on diversifying production, the factory’s management decided to take a risk and open its own meat canning shop. This success of this project signalled a new, promising direction in the company’s development. A decision was made to replace the presses for the manufacture of metal container ends. The first high-speed Karges Hammer press for the production of can lids was installed, which immediately increased production volumes.

From the Present to the Future

2008. The factory began upgrading its equipment and improving its production capacities, reaching its objective of 50 million packaging items per month. This complex, lengthy phase required significant investment.

2010. In November, the plant unveiled a new product: canned fish produced under the Sokhranim traditsii brand. Symbolically, the recipes this line is based on were developed in the 1950s by product engineers in Kaliningrad.

2011. As part of the equipment upgrade project, a new KBA-MetalPrint varnishing line with a capacity of 7,000 sheets per hour was introduced. A second fish canning line was launched, as a result of which the company’s canned products range was expanded to 45 items. Today, the fish canning shop has a capacity of 4 million cans.

2012. A rolled tin cutting line by LITTELL (USA) was acquired and commissioned, allowing the company to sharply increase production capacity and cut production costs for cans from the beginning of 2013. The lithography department was completely re-equipped with new pre-press CTP equipment manufactured by AGFA Graphics (Germany). This made the preparation of printing plates significantly easier and quicker. Investments in the modernization of production not only led to an increase in production capacity and a reduction in production costs, but also attracted new partners for long-term contracts.

2013. A KBA-Metalprint MetalStar-2 four-section high-speed printing press with LTG convection drying oven (Germany) was installed and commissioned. An automatic CLEVERTECH line (Italy) for packing metal cans with a diameter of 99.0 mm onto pallets was commissioned. A new Cantec (Germany) end-cutting line was commissioned for producing can lids with a diameter of 96.0 mm. One of the Soudronic welding lines was modified to manufacture composite cans of various heights with a tapered bottom and a diameter of 99.0/96.0 mm. One of the seamless can production lines was refitted with Blema Kircheis forming equipment to manufacture shaped HANSA cans.

2014. New equipment has been installed on the Soudronic assembly line No. 1 to increase output and expand the range of 72.8 mm diameter cans manufactured. Now we can manufacture cans with tapered and crimped can bodies.

The meat can production facility has been modernized to increase production capacity as well as the output and flexibility of the manufacturing steps. This development will ensure product quality continues to meet ever-increasing market requirements, and allows an HACCP system to be introduced at the plant in the future.

2015. A new palletizer has been installed for packaging cans 72.8 mm and 83.4 mm in diameter. Two new high-capacity Alfons Haar (Germany) production lines for 70 mm can bottoms and 99 mm seamless tapered cans, with Clevertech automatic palletizers, have been installed and placed in operation. A third KBA-MetalPrint painting line is now in operation for high-speed processing of enlarged print formats.

2016. In Smolensk Region the first new complex for the production of 72.8 mm cans, with a capacity of 15 million items per month, has lunched. The modernization of the canned meat processing facility has finished by completely retool with the latest equipment from Lagarde Autoclaves (France), Secma Cabon (France), and FMT (Italy).

2017. The Smolensk plant has launched a second production line, producing 83.4-mm welded tapered cans at a capacity of 15 million per month. To expand our product range, we have signed additional equipment supply contracts with Blema Kircheis (Germany) and Germann+Frei AG (Switzerland) to upgrade one of our production lines. We have commissioned a fourth palletizer, produced by Clevertech (Italy). We are now able to produce “Club” shaped seamless cans.

2018. New equipment from Alfons Haar (Germany) for the production of EOE 83 and EOE 99 easy-open lids, capable of producing 25 million units per month, has been brought on line, and a second Alfons Haar line producing type 1 (73x32 mm) and type 2 (99x27 mm) seamless cans has begun operation. We have modernized our line producing welded, tapered (cylindrical and ribbed) cans with a 72.8 mm diameter and a height of between 40 mm (for caviar) and 114 mm (for animal foods). Installation of new Blema Kircheis (Germany) and Germann+Frei AG (Switzerland) equipment has enabled us to expand the range of metal containers that we produce.

2019. The contract for the purchase of the fifth high-performance automatic line by Alfons Haar (Germany) to produce of 80 mm bottom covers was signed. The reconstruction of the plant’s global energy supply system has been completed. Some objects of internal infrastructure and auxiliary facilities has been modernized. There’s been arranged the site and access roads to the production complex of the branch in Rudnya, Smolensk region.

2020. At the end of 2020, a new hot water boiler house was installed and launched. The cost of the project is 25 million rubles. A new boiler house was put into operation, which made it possible to more efficiently use resources and reduce the cost of heating and hot water supply.

In the 4th quarter of 2020, the equipment for physical and chemical treatment of industrial effluents from food production by the German company "HUBER" was installed. In January 2021, the equipment was commissioned and adjusted. The implementation of this project allowed for better treatment of industrial wastewater, which significantly increases the safety of the ecosystem.